Steel Manufacturing

Our highly abrasion-resistant materials ROCK-WEL and Quick-Tip are used for the parts inside the steelworks used in harsh environments.

Super Wear Resistant Welding Method ROCK-WEL

Super Wear Resistant Material Actively Used in Various Fields

ROCK-WEL is a method of overlaying cemented carbide with high wear resistance by uniformly dispersing and fusing two types of super hard particles. Highly resistant against wear caused by impact, and by only changing the matrix material, the product will be resistant against corrosion in extreme temperatures as well.

ROCK-WEL = Ultra Hard Particles + Matrix

ROCK-WEL = Tungsten Carbide (WC) Grit + Matrix Material

According to the operating temperature, Matrix Material can be selected.

| ~200℃ | SS400 |

|---|---|

| ~600℃ | SUS410 |

| ~800℃ | SUS309 |

Particles and Cladding Material is Selected According to the Usage

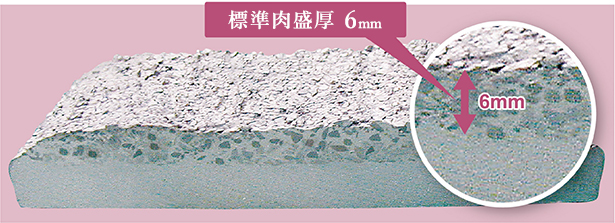

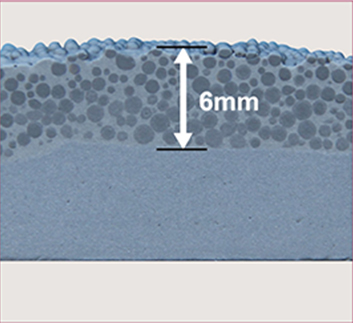

Cladding Thickness 6mm

2.3mm Bead Shape

2.3mm Bead Shape

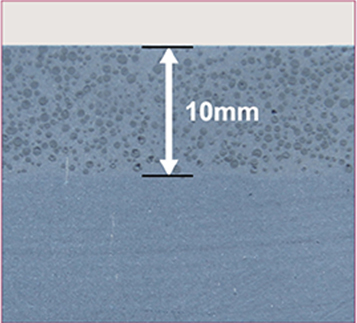

Cladding Thickness 10mm

0.7mm Bead Shape

0.7mm Bead Shape

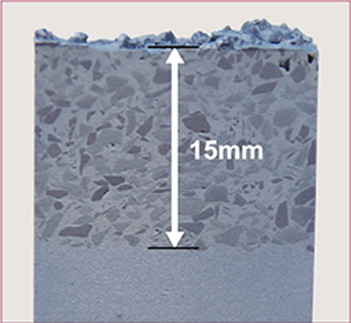

Cladding Thickness 15mm

0.71~2.6mm Crushed Grains

0.71~2.6mm Crushed Grains

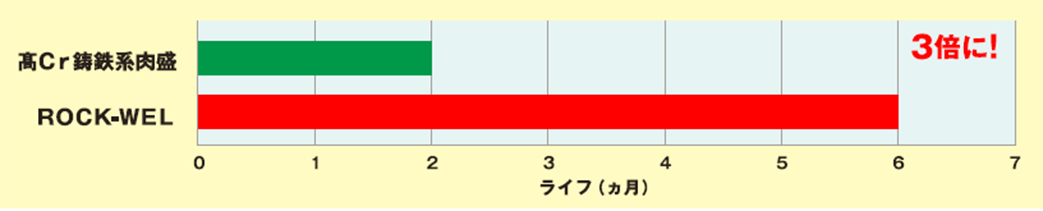

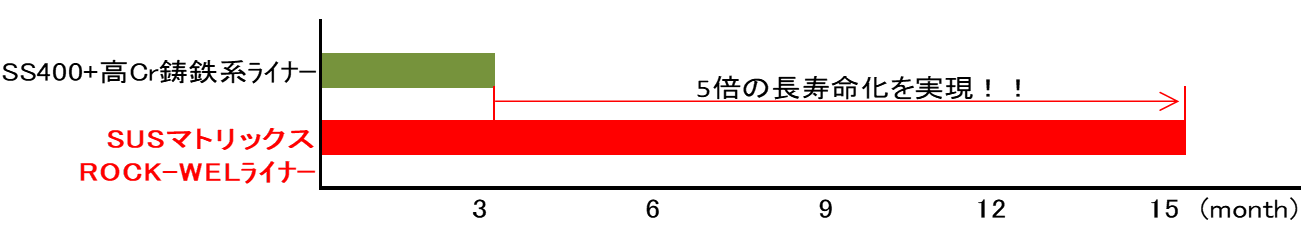

Example of Usage in Cold Rolling Mills

Example of Usage in Cold Rolling Mills

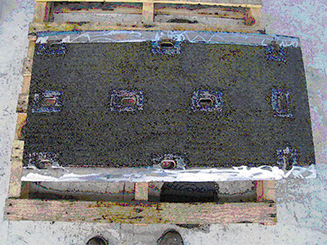

Liner Before Usage

After 15 Months of Usage

After 15 Months of Usage

ROCK-Wel : Slight wear, 5mm remaining on overlay

Other Examples

Coke Crushing Hammer

Iron Making Dust Shovel Blade

Crushing Hammer for Coke Dry Quenching Facilities